Vizoo's New physX Conversion Tool Streamlines Fabric Physical Property Measurement for Mills and Manufacturers

Vizoo’s physX™ Conversion addresses a critical industry bottleneck: the time-consuming measurement processes of fabric physical properties.

December 4, 2023

Digital product creation (DPC) is transforming every aspect of the garment industry. As brands shift to digital product design and replace physical garments with digital samples, the way fabric mills and manufacturers communicate and interact with those brands has also seen a significant shift. When scaling their DPC processes from product-specific programs into organization-wide initiatives, many brands are leaning on fabric mills to digitize their fabrics at the source.

”We aim to improve [DPC] across the supply chain [and] want vendors to avoid spending too much time digitizing a single fabric. Standardization and interoperability are crucial for this process. The physX Conversion tool is a big step in making this happen.

Martin SemschCEO - Vizoo

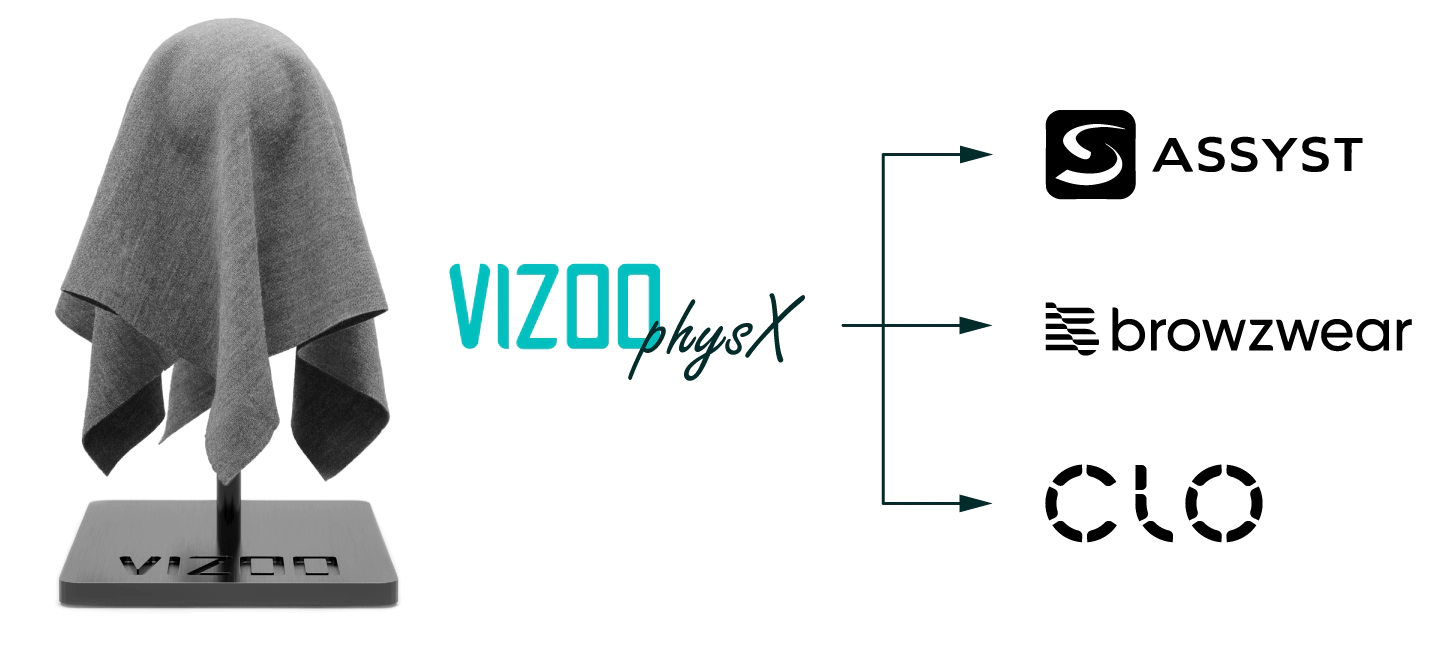

Multiple 3D CAD applications are used across the apparel industry, each with its own physical property measurement processes and tools. Additionally, the measurements from each CAD-specific process are incompatible with other CAD applications.

As a result, when catering to diverse brand clients with varied 3D software integrated into their workflows, fabric mills must measure the physical properties for each software separately. This inefficient workflow can stretch the measurement of one single fabric into hours of work.

Fabric Mills Digitizing Their Offering Face a Relatively High Workload Requiring Multiple Measurement Processes

At least, this has been the case until now. With the inefficient and disjointed state of physical property digitization, especially for fabric mills working with multiple brand clients, Vizoo saw the need for a new solution to streamline these processes.

The newly released physX Conversion tool enables a highly efficient workflow by converting the parameters from a single fabric measurement routine into accurate fabric properties compatible with multiple 3D CAD applications like Browzwear, CLO3D, and Assyst.

Clients taking advantage of the tool for dual output to CLO3D and Browzwear have already seen a substantial 50% reduction in fabric usage and a 40% time savings, providing a direct, positive impact on their digitization throughput and waste reduction initiatives.

physX Conversion Adds an Instant Boost of Efficiency and Sustainability to Fabric Measurement

”physX Conversion is a tremendous value add for manufacturers and brands. I work closely with both sides and am happy to see such efficiency initiatives in the 3D space. In my role as DPC Lead for Artistic Milliners and Star Fades International, I have seen an immediate benefit by saving time and achieving consistent results in the measurement process.

Amber IsaacDPC Lead - Artistic Milliners and SFI

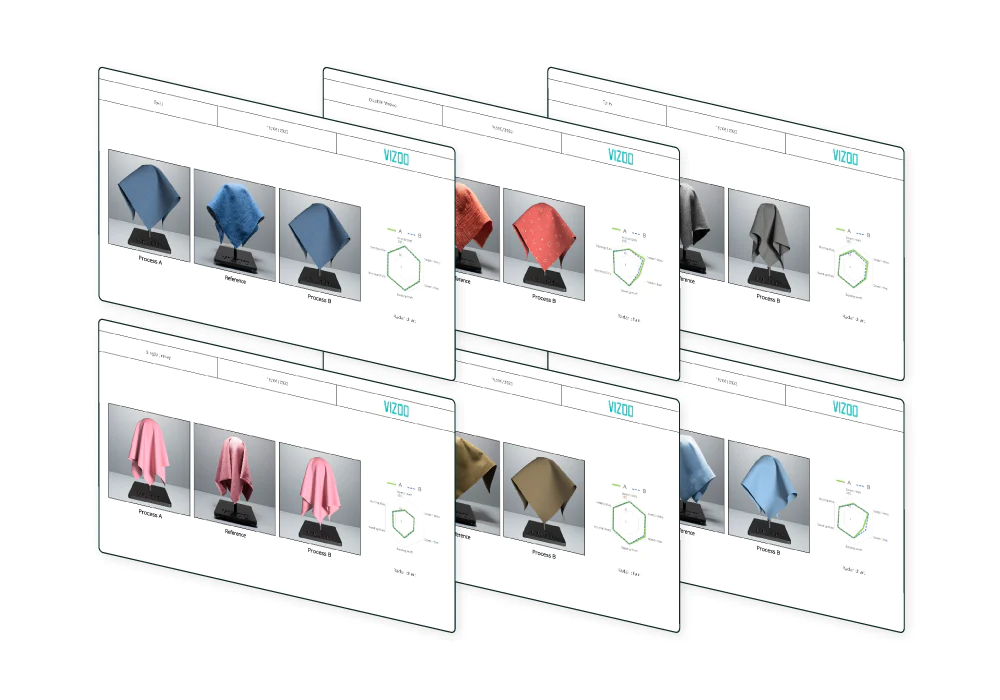

In addition to the substantial savings, the physX Conversion algorithm caters to the highest quality expectation of scaled digital product creation. Extensive internal testing during development and by Vizoo clients during pre-release has shown that the converted results are not only as accurate as native measurement processes but they also help reduce the variance typically seen when comparing fabric simulations between 3D CAD applications.

Industry Approved: The physX Conversion Workflow is Validated by Industry Experts

During the development phase, Vizoo partnered with the University of AMFI, which dedicated a master’s thesis to conducting the underlying research for the conversion of physics. The scope included the problem of simulation across multiple 3D tools and benchmarking the solution using a tool like physX Conversion.

The research concluded with a survey of an impartial panel of industry professionals who conducted a visual analysis on a sample set and determined that the conversion simulation was identical or very close to the original measurements’ simulation. Additional statistical analysis of the physical property data shows minimal to no data loss after conversion.

Martin Semsch, CEO of Vizoo, states, “We aim to improve the way we create digital products across the supply chain to make it more efficient. To achieve this, we want vendors to avoid spending too much time digitizing a single fabric. Standardization and interoperability are crucial for this process. The physX Conversion tool is a big step in making this happen.”