Company Profile

Industry: Apparel

Location: Taiwan

Vizoo Client Since: 2020

Makalot Industrial Co., Ltd., a leading apparel manufacturer based in Taiwan, has been a pioneer in Digital Product Creation (DPC) since 2006, long before the fashion industry fully recognized the potential of digital workflows.

Elly Cheng, Director of Digital Product Creation at Makalot, shares that this ambition to succeed is a central driving force in whatever they do.

”We consistently prioritize innovation and excellence in all aspects of our operations. This includes investing in advanced technologies like Digital Product Creation (DPC) to stay ahead of industry trends and meet evolving market demands. We foster a culture of continuous improvement, encouraging employees to pursue professional development and stay updated with the latest industry advancements. This relentless pursuit of success ensures we remain a leader in the apparel industry.

Elly ChengDirector of DPC at Makalot

This tenacity made the company resilient and able to weather challenging times throughout history. Founded during a shakeup in Taiwan’s garment industry in the 80s and 90s, when most of the apparel production was being moved offshore, Frank Chou, the founder, refused to give up and built Makalot with his partners from scratch.

Today, with over 37,000 employees and annual revenues of €967 million, Makalot’s commitment to innovation continues to drive supply chain resilience and operational efficiency, positioning the company as a forward-thinking leader in the global apparel market.

The Early Adoption of DPC at Makalot

Early discovery of DPC was circumstantial, but deployment was intentional and strategic. Initially, the team began to use DPC to support the development of maternity wear for a client, leading to the purchase of their first 3D software for trial use.

Elly expounds, “Subsequently, we recognized the profound impact of digital technology on the future market and foresaw that digitization would play an increasingly important role in the apparel industry. Therefore, we decided to strategically plan ahead and establish a robust digital product creation infrastructure. This not only allows us to respond quickly to market changes but also gives us a competitive edge.”

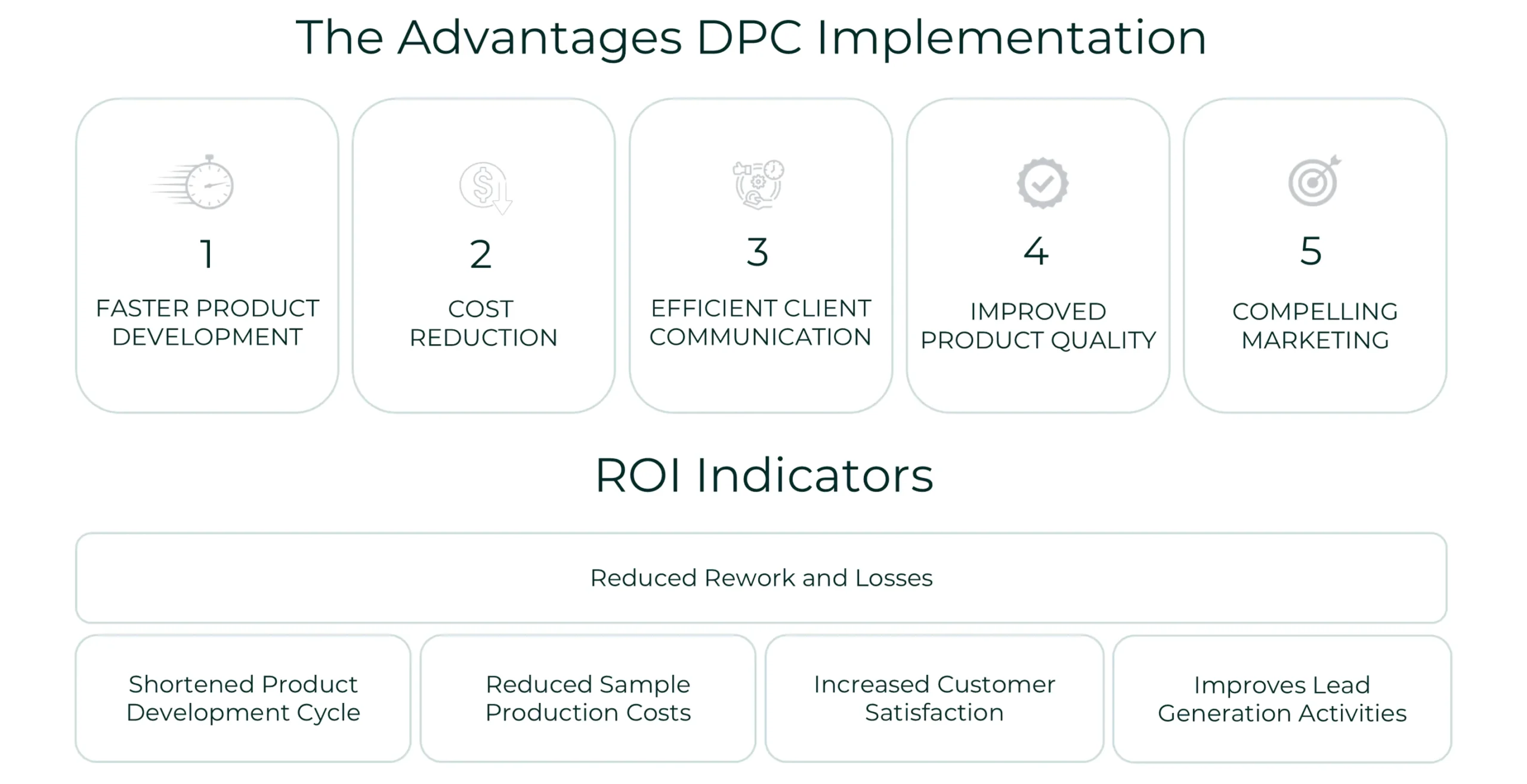

DPC Advantages and Measuring the Return on Investment

According to Elly, there were several benefits from the implementation, each one measured through various indicators.

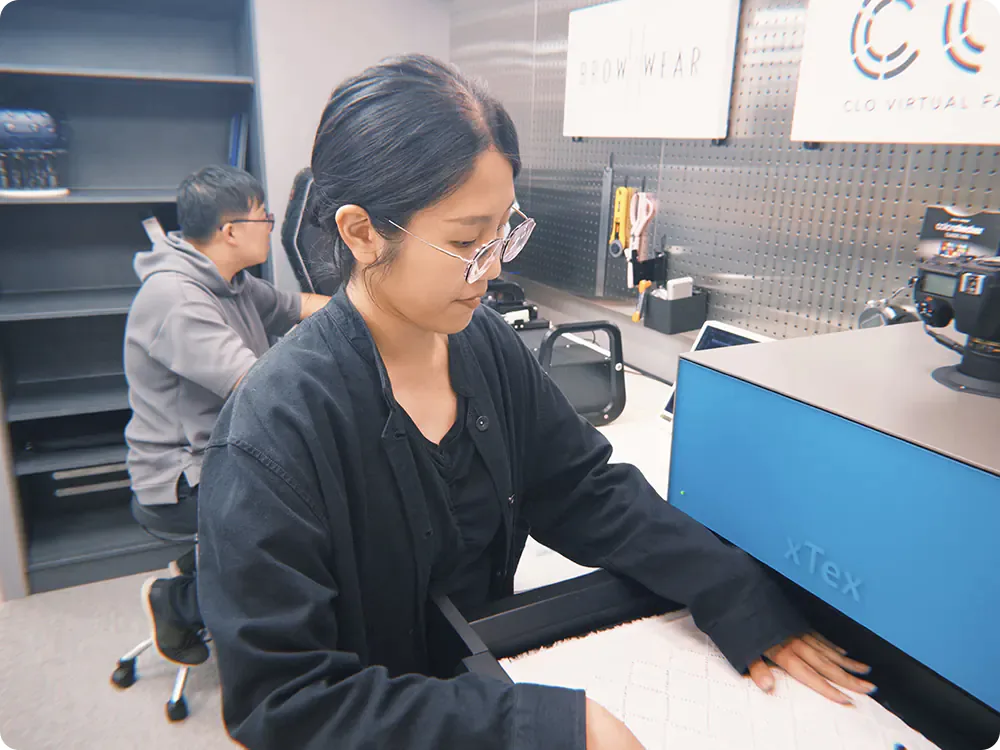

Vizoo Technology as Key Differentiator in Makalot's DPC

According to Elly, Vizoo’s xTex technology provided a key difference in their DPC Implementation. The team chose Vizoo xTex because they wanted to make their digital product creation process more precise and efficient, which they achieved through Vizoo’s high-quality material scanning and intuitive software editing services.

Elly further expounds: “After using Vizoo tools, our material data has become more realistic, with richer texture details, greatly enhancing the visual effect and market competitiveness of the final product. Vizoo’s leading technology and stability allow us to accurately capture and reproduce material details in the design process.”

With the gap in material precision filled in the digitization process, the entire design and development process has become smoother for the team at Makalot. This means lessening or totally avoiding rework or communication issues caused by blurry images and improving production efficiency.

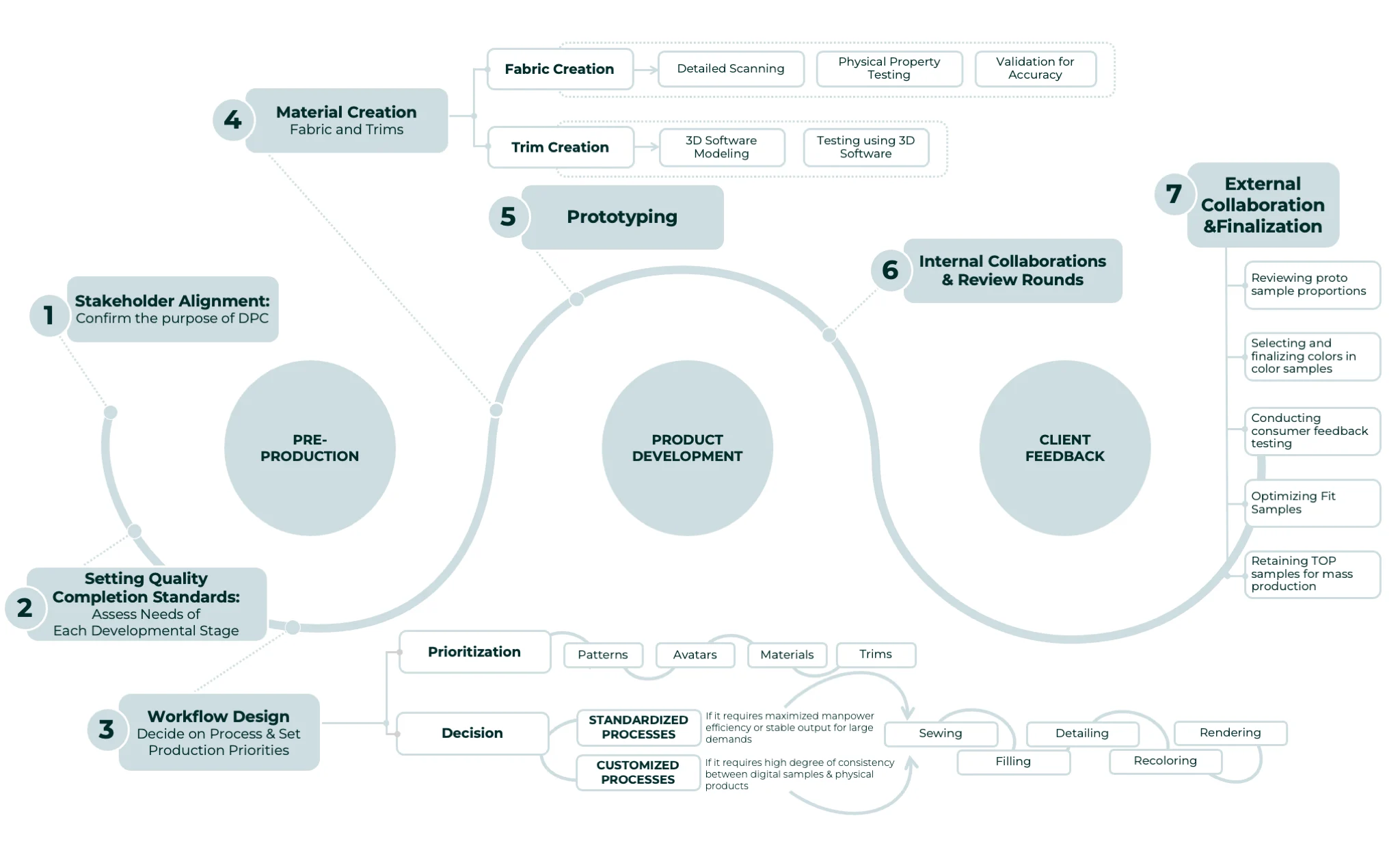

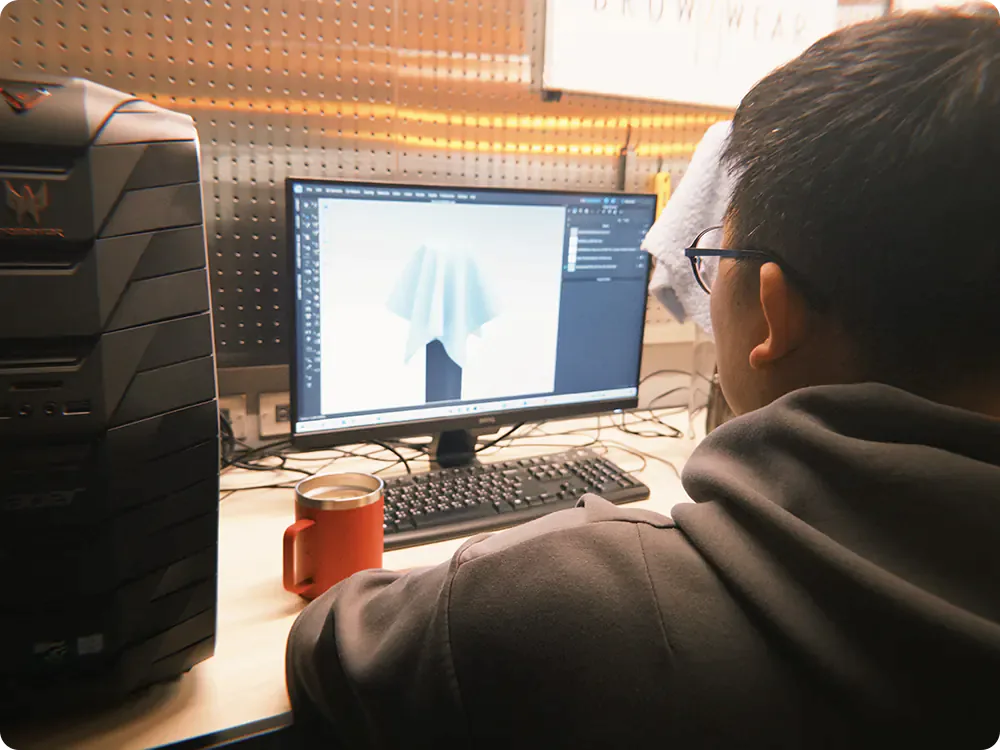

A Look Inside Makalot's DPC Process

Through careful planning and taking advantage of DPC technology at various points of production, Makalot is able to increase the accuracy, efficiency, and speed of their product development, improve their internal processes, and boost their customer satisfaction.

Looking at the Future

Leading the pack towards Digital Product Creation was only the start for the team at Makalot. As its next frontier, the company tackles sustainability by embracing digital transformation and technology.

Elly shares that ongoing initiatives include incorporating sustainable materials and processes and leveraging automation & AI to increase efficiency and help minimize their environmental impact.

She concludes: “Our vision for the future combines technological innovation with a strong commitment to sustainability, positioning us to lead the apparel industry into a new era of responsible and forward-thinking production.”

This case study is a joint collaboration between Vizoo and Makalot – November 2024

About Makalot

Makalot Industrial Co., Ltd. is a leading global apparel manufacturer based in Taiwan. The company specializes in providing flexible and diverse production services to international brands, offering design, development, and manufacturing of a wide range of apparel. With a strong focus on innovation, efficiency, and quality, Makalot serves as a key partner for many well-known global fashion brands. Their commitment to sustainability and social responsibility is evident through their efforts in maintaining ethical labor practices and reducing environmental impact.

About Vizoo

Vizoo is the number one supplier of solutions for the physically accurate digitization of material swatches. Since 2013, automotive, apparel, footwear, home fashion brands and their suppliers have relied on Vizoo’s xTex system to digitize their material processes and create digital twins of physical material samples. To date, the company has developed an extensive network of more than 500 customers and is distributing their systems to more than 40 countries globally.

Ready to Digitize Your Business?

Request a live demo, share your 3D project needs, or ask questions about our capabilities.

Get in Touch